Gitoya ya Diameter Furnace Graphite Electrode kumatara ya arc yumuriro wibyuma ninganda

Ikigereranyo cya tekiniki

Imbonerahamwe 1: Ikigereranyo cya tekiniki ya Diameter Ntoya ya Graphite Electrode

| Diameter | Igice | Kurwanya | Imbaraga zoroshye | Umusore Modulus | Ubucucike | CTE | Ivu | |

| Inch | mm | μΩ · m | MPa | GPa | g / cm3 | × 10-6/ ℃ | % | |

| 3 | 75 | Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Amabere | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 4 | 100 | Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Amabere | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 6 | 150 | Electrode | 7.5-8.5 | .5 8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Amabere | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 8 | 200 | Electrode | 7.5-8.5 | .5 8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Amabere | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 9 | 225 | Electrode | 7.5-8.5 | .5 8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Amabere | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 10 | 250 | Electrode | 7.5-8.5 | .5 8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Amabere | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

Imbonerahamwe 2: Ubushobozi bwo Gutwara Ubu Kuri Diameter Ntoya ya Graphite Electrode

| Diameter | Umutwaro uriho | Ubucucike bwa none | Diameter | Umutwaro uriho | Ubucucike bwa none | ||

| Inch | mm | A | A / m2 | Inch | mm | A | A / m2 |

| 3 | 75 | 1000-1400 | 22-31 | 6 | 150 | 3000-4500 | 16-25 |

| 4 | 100 | 1500-2400 | 19-30 | 8 | 200 | 5000-6900 | 15-21 |

| 5 | 130 | 2200-3400 | 17-26 | 10 | 250 | 7000-10000 | 14-20 |

Imbonerahamwe 3: Graphite Electrode Ingano & Tolerance Kuri Diameter Ntoya Graphite Electrode

| Diameter | Diameter nyayo (mm) | Uburebure bw'izina | Ubworoherane | |||

| Inch | mm | Icyiza. | Min. | mm | Inch | mm |

| 3 | 75 | 77 | 74 | 1000 | 40 | -75 ~ + 50 |

| 4 | 100 | 102 | 99 | 1200 | 48 | -75 ~ + 50 |

| 6 | 150 | 154 | 151 | 1600 | 60 | ± 100 |

| 8 | 200 | 204 | 201 | 1600 | 60 | ± 100 |

| 9 | 225 | 230 | 226 | 1600/1800 | 60/72 | ± 100 |

| 10 | 250 | 256 | 252 | 1600/1800 | 60/72 | ± 100 |

Porogaramu nyamukuru

- Kalisiyumu karbide gushonga

- Umusaruro wa Carborundum

- Gutunganya Corundum

- Ntibisanzwe gushonga

- Uruganda rwa Ferrosilicon

Amabwiriza Gutanga no Gukoresha Graphite Electrode

1.Kuraho igifuniko cyo gukingira umwobo mushya wa electrode, reba niba urudodo rwo mu mwobo wa electrode rwuzuye kandi urudodo rutuzuye, hamagara abajenjeri babigize umwuga kugirango umenye niba electrode ishobora gukoreshwa;

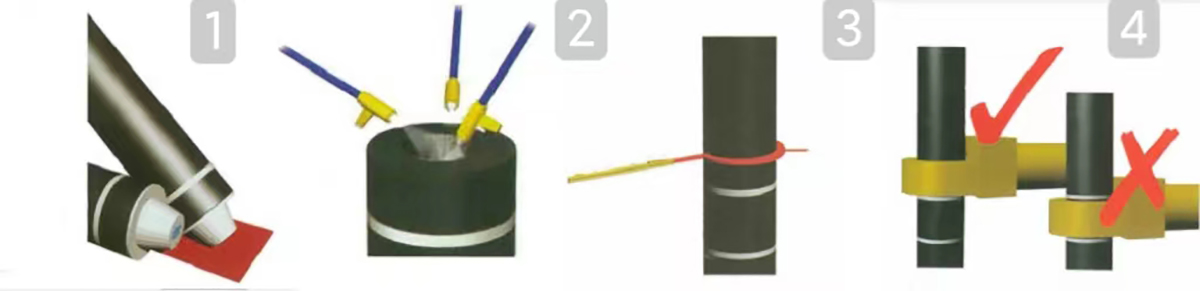

2.Kuramo icyuma cya electrode mu mwobo wa electrode ku mpera imwe, hanyuma ushire umusego woroshye munsi y’urundi ruhande rwa electrode kugirango wirinde kwangiza ingingo ya electrode; (reba pic1)

3.Koresha umwuka wugarije kugirango uhindure umukungugu nizuba hejuru yumwobo nu mwobo wa electrode ihuza, hanyuma usukure hejuru nuhuza electrode nshya, ubisukure hamwe na brush; (reba pic2)

4.Kura electrode nshya hejuru ya electrode itegereje kugirango uhuze nu mwobo wa electrode hanyuma ugwe buhoro;

5.Koresha agaciro gakwiye kugirango ufunge neza electrode; (reba pic3)

6.Ufite amashanyarazi agomba gushyirwa hanze yumurongo wo gutabaza. (Reba pic4)

7.Mu gihe cyo gutunganya, biroroshye gukora electrode yoroheje kandi igatera kumeneka, kugwa hamwe, kongera ikoreshwa rya electrode, nyamuneka ntukoreshe electrode kugirango uzamure karubone.

8.Kubera ibikoresho bitandukanye bikoreshwa na buri ruganda nuburyo bwo gukora, ibintu bifatika na chimique ya electrode hamwe ningingo ya buriwukora. Mugukoresha rero, mubihe rusange, Nyamuneka ntukavange ukoreshe electrode hamwe ningingo zakozwe nababikora batandukanye.